This site uses cookies to help give you the best possible user experience. By continuing to browse this site you give consent for cookies to be used!

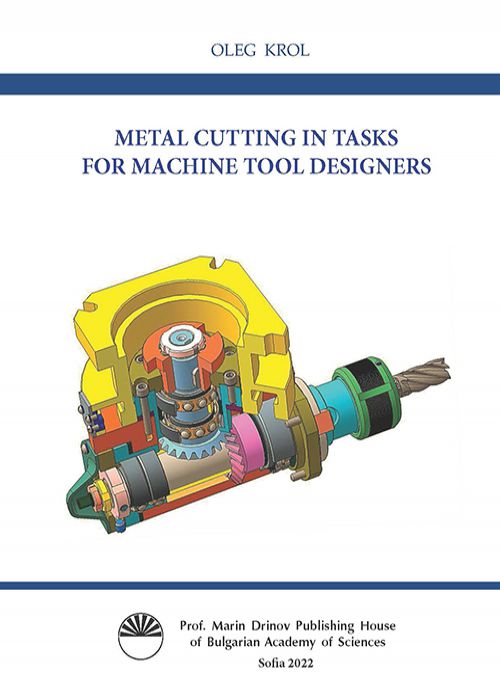

METAL CUTTING IN TASKS FOR MACHINE TOOL DESIGNERS

Oleg Krol

Year of Publication: 2022

Category: Information and Communication Sciences and Technologies

Language: English

Summary

In the monograph, the theoretical and logical bases of solving problems related to the

research of the cutting process of structural steels and alloys are considered. The approach

to the study of cutting tool geometry based on a logical analysis chain a research of cutting

wedge geometrical parameters from the cutting scheme construction through the coordinate

planes to the angles of a cutting tool is carried out. Problem solution on determining

kinematic angles of cutters when machining curvilinear contour on NC machine is

considered. Analysis of various physical phenomena occurring at metal excess layer

removal from the workpiece is performed. Study of physical phenomena is based on the

concept of the term "Cutting" as a set of simultaneously performed processes of elasticplastic

deformation of the cut layer, cutting tool wear and blunting as well as the formation

of the machined surface of the part. The peculiarity of the cutting tool wear process taking

into account the simultaneous effect of abrasive, adhesive, thermal and oxidative effects in

the process of cutting is noted. The analytical apparatus and algorithms of optimum cutting

modes search with the use of linear and geometrical programming methods and Lagrange

multipliers method are given. A software-methodological complex geometrical

programming for solving nonlinear problem with components in positive posinomials form

is implemented. A software-methodological complex on based Lagrange multipliers

method for determine a qualitative picture of cutting processes when the structure and

modes change is implemented.

research of the cutting process of structural steels and alloys are considered. The approach

to the study of cutting tool geometry based on a logical analysis chain a research of cutting

wedge geometrical parameters from the cutting scheme construction through the coordinate

planes to the angles of a cutting tool is carried out. Problem solution on determining

kinematic angles of cutters when machining curvilinear contour on NC machine is

considered. Analysis of various physical phenomena occurring at metal excess layer

removal from the workpiece is performed. Study of physical phenomena is based on the

concept of the term "Cutting" as a set of simultaneously performed processes of elasticplastic

deformation of the cut layer, cutting tool wear and blunting as well as the formation

of the machined surface of the part. The peculiarity of the cutting tool wear process taking

into account the simultaneous effect of abrasive, adhesive, thermal and oxidative effects in

the process of cutting is noted. The analytical apparatus and algorithms of optimum cutting

modes search with the use of linear and geometrical programming methods and Lagrange

multipliers method are given. A software-methodological complex geometrical

programming for solving nonlinear problem with components in positive posinomials form

is implemented. A software-methodological complex on based Lagrange multipliers

method for determine a qualitative picture of cutting processes when the structure and

modes change is implemented.

Аbout The Author

Specifications

ISBN: 978-619-245-218-6

Year of Publication: 2022

Category: Information and Communication Sciences and Technologies

Language: English

en

en Български

Български